The key to inhibiting heat conduction lies in using materials with low thermal conductivity (λ). Thermal conductivity is a physical quantity that measures the ability of a substance to conduct heat; the smaller its value, the weaker the heat conduction ability, and the better the insulation performance.

Common Mechanisms to Reduce Heat Conduction:

• Using porous materials: Most insulation materials (e.g., foam plastic, rock wool, glass wool) are porous. The air (or inert gas) sealed in the pores has an extremely low thermal conductivity (air λ ≈ 0.026 W/(m·K) at 20°C, much lower than that of metals like iron λ ≈ 80 W/(m·K)). These pores block the direct contact between the solid components of the material, significantly reducing heat conduction through the solid.• Using vacuum insulation: In vacuum insulation panels (VIPs), most of the air in the insulation layer is pumped out to form a high vacuum. Since there are almost no molecules in a vacuum to collide and transfer heat, heat conduction is minimized to an extremely low level. This is why vacuum flasks can keep liquids hot or cold for a long time.

Thermal insulation materials and structures suppress convection bypreventing the free flow of fluids:•Sealing porous structures: The pores in insulation materials (e.g., expanded polystyrene, EPS) are small and closed. This prevents the air inside the pores from forming large-scale convection currents; only minimal"micro-convection" occurs in tiny pores, which has a negligible effect on heat transfer.

Thermal insulation for radiation mainly relies on reflectingorabsorbing radiant heat: •Reflecting thermal radiation: Materials with high reflectivity (e.g., aluminum foil, metalized film) are used. These materials can reflect most of the incident infrared radiation (reflectivity > 90%) back to the heat source, preventing radiant heat from entering the insulated space. For example: ◦The inner layer of a vacuum flask is coated with a thin metal film (usually silver) to reflect the thermal radiation of the liquid inside, reducing heat loss.

•A vacuum flask uses a vacuum layer to inhibit conduction and convection, plus a metal coating to reflect thermal radiation—three mechanisms work together to achieve long-term temperature retention.

In short, the essence of thermal insulation is to target the three pathways of heat transfer, using material selection, structural design, and process optimization to weaken or block heat flow, ultimately maintaining the temperature stability of the protected object or space.

Customization Unlimited

Competitiveness High

Premium Outlook

Product Quality

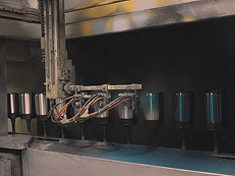

Pioneer & Leader in Water Bottle Ceramic Coatings

Soniu holds a landmark position in water bottle innovation—it is the first company globally to develop ceramic coatings tailored for water bottles, and today stands as the undisputed leader in this field. What began as a quest to elevate daily hydration has evolved into a legacy of technical advancement, blending user-centric practicality with cutting-edge science.

When Soniu first launched its ceramic coating, it addressed two key user pain points: effortless cleaning and preserved beverage flavor. Unlike traditional metal or plastic linings that trap stains and metallic odors , Soniu’s initial ceramic formula featured an ultra-smooth, non-porous surface. Spills and residues wipe away with a simple rinse, no harsh scrubbing needed; more importantly, it keeps the unique notes of drinks, ensuring every sip of coffee,juice, tea, or water tastes exactly as intended—no"aftertaste" from the bottle itself.

Driven by a commitment to innovation, Soniu has since achieved remarkable technical breakthroughs, elevating its ceramic coating to deliver powerful antibacterial protection. Through refined material science and precision engineering, the latest iteration of its ceramic coating actively inhibits the growth of common harmful bacteria, including E. coli and Staphylococcus aureus, with a proven antibacterial rate of over 99.9%. This is a game-changer for daily use: whether the bottle is shared among family members, used in busy offices, or carried during commutes, it minimizes the risk of bacterial contamination, adding an extra layer of safety to hydration.

As the leader in ceramic-coated water bottles, Soniu’s journey—from pioneering easy-clean, flavor-preserving coatings to mastering antibacterial technology—reflects its dedication to making hydration safer, more enjoyable, and more reliable. For users worldwide, Soniu isn’t just a brand; it’s the gold standard for ceramic coating excellence.

With NIU Bottle

What Do Our Customers Say

Lily

Our Customer

Jackson Reynolds

Our Customer

Fiona

Our Customer

For OEM items, pls contact us for further discuss.

But a little sample charge for custom designs. Samples charge is refundable when order is up to certain quantity.

If you want your designs, about 5 days will be ready, subject to you designs whether they need new printing screen, etc.

If customized OEM order, It takes 15-25 days after received deposit and all packing materials are confirmed.

For small order, it's 100% payment inadvance through alibaba.

English

English